The weekly circular has been a cornerstone of retail marketing for decades. Those colorful flyers arriving in your mailbox or newspaper announcing this week’s deals remain remarkably effective at driving shoppers through store doors. Yet behind the familiar format lies a transformation that’s reshaping how these essential marketing materials come to life.

Retailers are increasingly turning to automation to produce their weekly circulars, and the results go far beyond simply speeding up production. This shift is enabling businesses to manage inventory more intelligently, respond more quickly to market conditions, and ultimately serve customers better – all while significantly reducing costs.

The Traditional Weekly Circular Production Challenge

Creating a weekly circular used to be an exhausting race against time. Product managers would manually select items to feature, designers would hunt through files for product images and pricing data, and teams would spend days on proofing cycles to catch errors before print deadlines. For large retailers with hundreds of locations across different regions, the complexity multiplied—each market might need its own version reflecting local preferences, inventory levels, and competitive pricing.

The process was not only time-consuming but also inflexible. By the time offers were finalized, designed, proofed, and sent to print, market conditions might have already shifted. Slow-moving inventory that desperately needed promotion might sit on shelves while the weekly circular featured products that didn’t need the boost.

How Automation Is Changing the Game

Modern weekly circular production platforms are fundamentally reimagining this workflow by connecting directly to retailers’ product information management (PIM) and digital asset management (DAM) systems. Instead of designers manually placing each product image and typing in prices, automation pulls this information directly from central databases where it’s already maintained.

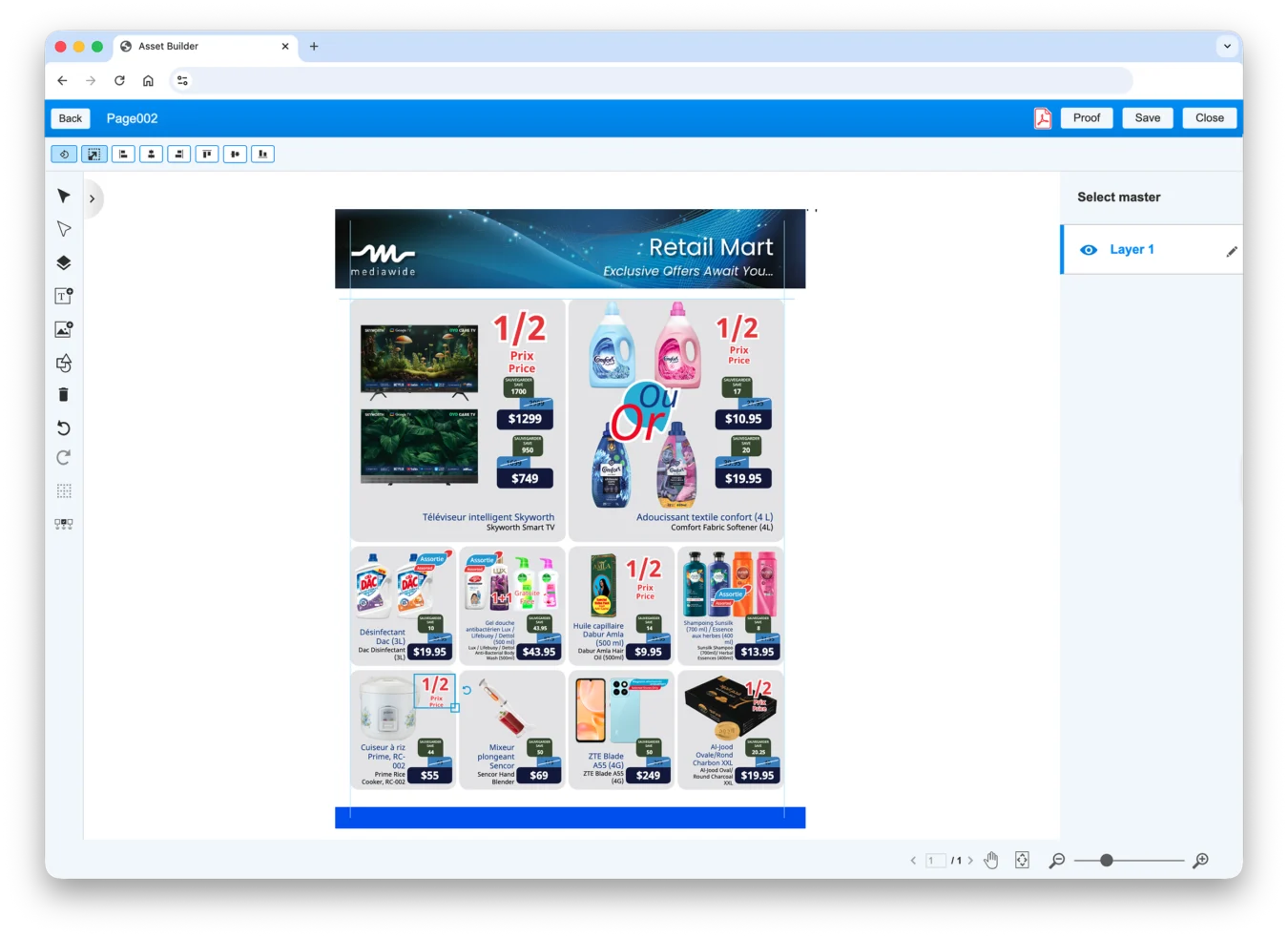

Platforms used by retailers exemplify this approach. The system integrates with Adobe InDesign through specialized plugins that allow automatic page building. Merchandisers can prioritize which products to feature—perhaps items with high margins or excess inventory that needs to move—and the system automatically generates layouts complete with current pricing, product descriptions, and professionally formatted images.

This integration eliminates the manual data entry that previously consumed hours of labor while also dramatically reducing errors. When pricing changes in the central system, it updates automatically across all channels. There’s no risk of a flyer going to print with yesterday’s prices or products that have been discontinued.

Real Cost Savings from Automation

The financial impact of automating weekly circular production extends across multiple dimensions. Labor costs drop substantially when teams no longer spend hours on repetitive tasks like data entry and image placement. One analysis of retail automation found that companies typically reduce processing times from several hours to just minutes for similar workflows.

The reduction in errors delivers its own savings. Manual weekly circular production carried error rates of around three to five percent, leading to costly corrections, customer complaints, and lost sales opportunities. Automated systems reduce these errors to below one percent through real-time data validation.

Perhaps most significantly, automation compresses production cycles. What once took several days can now happen in hours, enabling retailers to respond to market dynamics much faster. When a competitor launches an unexpected promotion or inventory levels shift suddenly, automated systems allow retailers to adjust their weekly circulars right up until production deadlines.

A case study from a UK supermarket found that automating just their markdown and clearance process—closely related to weekly circular production—could generate a six percent revenue uplift worth approximately £18 million annually. The efficiency gains came from better decision-making enabled by real-time data and the elimination of manual processes prone to delays and errors.

Turning Weekly Circulars Into Inventory Management Tools

One of automation’s most valuable contributions is transforming weekly circulars from purely promotional tools into strategic inventory management instruments. Retailers can now use their automated systems to identify slow-moving products or items approaching expiration and automatically feature them in upcoming weekly circulars.

One platform demonstrates this approach by generating custom bi-weekly flyers specifically promoting products nearing expiration or representing slow-moving stock. The system analyzes real-time inventory data, identifies which items need promotional support, and automatically generates flyers designed to boost their turnover.

This capability addresses a critical retail challenge: balancing inventory levels to avoid both stockouts and overstocking. By using weekly circulars to accelerate sales of specific products, retailers can improve inventory turnover rates, reduce waste from expired goods, and free up capital tied up in slow-moving stock.

AI-powered systems can even predict which products are likely to become overstocked based on historical sales patterns and market trends, enabling proactive promotional strategies before inventory problems develop. Dynamic pricing algorithms automatically adjust discounts on clearance items based on real-time demand, competitor pricing, and inventory levels to optimize both sales velocity and profitability.

Reducing Delays and Increasing Agility

Speed matters tremendously in retail promotions. Supply and demand dynamics, competitive actions, and seasonal factors can shift rapidly. Automated weekly circular production dramatically shortens the time from concept to distribution.

Traditional workflows required products and offers to be finalized days or even weeks before weekly circulars reached customers. Automated systems compress this timeline, with some retailers now able to make adjustments just hours before final production. This agility means weekly circulars can reflect current market realities rather than outdated assumptions.

The automation platform developed by Mediawide showcases how grid-based templates combined with intelligent algorithms can handle complex layout challenges automatically. The system can adjust product layouts on the fly based on the amount of text needed or the number of images per product, solving design challenges that previously required manual intervention.

Bridging Print and Digital Channels

Today’s automated weekly circular systems don’t just produce print materials—they seamlessly generate digital versions for websites, mobile apps, and email campaigns from the same source data. This multichannel approach ensures consistency across all customer touchpoints while dramatically reducing the work required.

Platforms export weekly circular content developed for print automatically to digital equivalents, complete with interactive features like clickable products that link directly to e-commerce checkout or loyalty program integration. QR codes can be embedded in print versions to bridge the physical and digital experiences, directing customers to personalized mobile offers.

This integration supports personalization at scale. While print weekly circulars reach broad audiences with general offers, the digital versions can be customized based on individual customer purchase history and preferences. A customer who regularly buys organic produce might see different featured items in their digital weekly circular compared to someone focused on budget-friendly staples.

Managing Versions and Variations

Large retailers often need dozens or even hundreds of versions of each weekly circular to account for regional preferences, store formats, language requirements, and local inventory availability. Automation makes this complexity manageable.

Systems can automatically generate all required versions from a single master weekly circular, applying regional pricing, swapping products based on local inventory, and translating content as needed. What once required separate manual production for each version now happens automatically, with built-in quality controls ensuring consistency across all variations.

The Human Element Remains Essential

Despite all this automation, successful weekly circular production still requires human judgment and creativity. Merchandisers decide which strategic products to promote and what story the weekly circular should tell. Designers establish the visual framework and brand standards that automated systems follow. Marketing teams craft compelling copy that resonates with customers.

The difference is that these professionals now spend their time on strategic, creative work rather than repetitive production tasks. Automation handles the mechanics, freeing people to focus on what drives results: understanding customer needs, identifying promotional opportunities, and creating compelling offers.

Looking Forward

As automation technology continues advancing, we’re seeing new capabilities emerge. AI is beginning to help retailers predict which products will resonate with specific customer segments, suggest optimal promotional timing based on historical patterns, and even generate initial creative concepts for human review and refinement.

Machine learning algorithms continuously improve by analyzing which promotional strategies perform best, feeding these insights back into future weekly circular planning. The systems become smarter over time, helping retailers make increasingly effective decisions about what to promote, when, and to whom.

The Bottom Line

Automation is transforming retail weekly circular production from a labor-intensive, error-prone process into a streamlined, data-driven marketing engine. The benefits extend well beyond simple cost savings, though those are substantial. Retailers gain agility to respond to market changes, tools to manage inventory more intelligently, and the ability to deliver more personalized, relevant promotions to customers.

The weekly circular itself isn’t disappearing – research shows it remains highly effective at driving store traffic and sales. But the way these circulars come to life has fundamentally changed. By embracing automation, retailers are making their most traditional marketing tool work harder and smarter than ever before, ultimately serving customers better while running more efficient operations.

For retailers still relying on manual weekly circular production, the question isn’t whether to automate, but when. The technology has matured, the business case is compelling, and the competitive advantages are clear. Those who embrace these tools thoughtfully—keeping the human judgment and creativity at the center while letting automation handle the mechanics—will find themselves better positioned to thrive in an increasingly dynamic retail landscape.

Ready To Streamline Your Weekly Circular Production?

Discover how the Mediawide Creative Platform for Retail Circulars can help your business create high-quality, data-driven promotional flyers with unmatched efficiency, using automation.

Leave a Reply